Explore how the ancient pottery kiln shaped early civilizations through art, technology, and daily life.

Key Highlights

- Pottery kilns have evolved over thousands of years, with early designs like pit kilns advancing to complex beehive and updraft models.

- • Archaeological finds such as the Yarim Tepe site reveal important insights into ancient pottery kiln construction and firing processes.

- Different civilizations, including Greece, China, and Japan, developed unique kiln technologies and firing methods tailored to their resources and needs.

- The choice of fuel, from firewood to hardwood and even animal dung, shaped the outcomes and characteristics of ancient ceramics.

- Modern experimental archaeology continues to recreate and analyze ancient kiln designs to better understand historical ceramic production.

- The evolution of kiln technology, from rudimentary earthen structures to modern gas and electric kilns, reflects ongoing innovation in temperature control and efficiency.

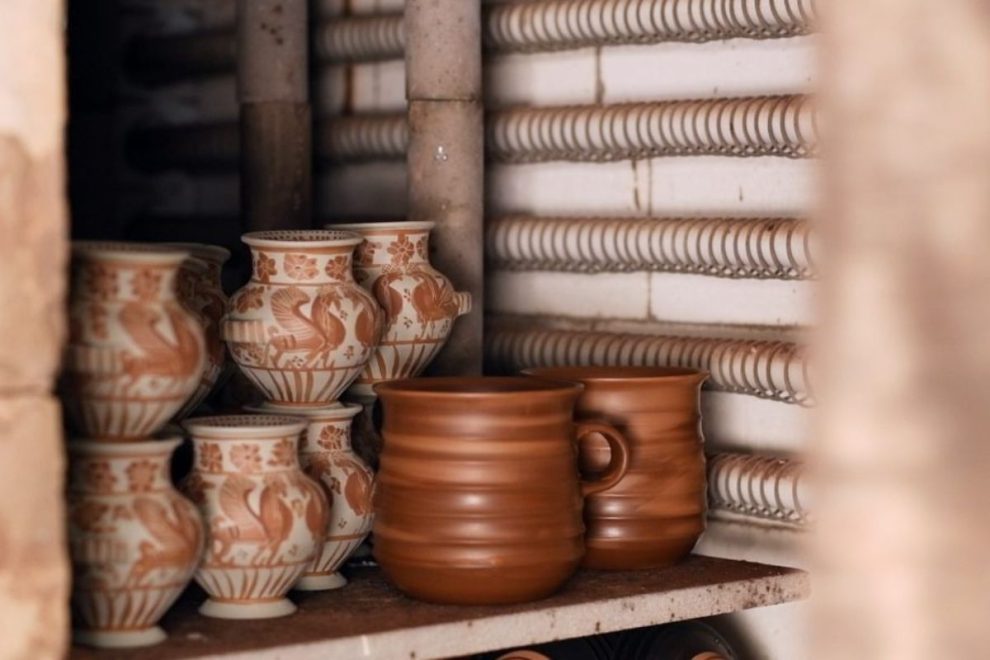

Pottery kilns have played a crucial role in shaping human culture and technology for millennia. These chambers, designed to reach high temperatures, transformed clay into durable pottery, tiles, and brick. The firing process, first managed in simple pit kilns, steadily advanced as ancient pottery kiln designs became more sophisticated. Today, the study of historical kiln technology provides valuable insights into how early societies crafted not only functional objects but also works of art, reflecting their everyday needs and creative ambitions.

Etymology and Pronunciation of “Kiln”

The term “kiln” finds its roots in Old English, where it appeared as “cyline,” “cylene,” or “cyln(e),” itself derived from the Latin “culina,” meaning “kitchen.” Over time, the word evolved through Middle English spellings such as “kulne,” “kilne,” and “kyll,” before settling into its modern form. In Greek, the word “kaiein” translates to “to burn,” further underlining the kiln’s fiery purpose.

Pronunciation of “kiln” has shifted over the centuries. Historically, the “n” was silent—so “kiln” was pronounced exactly like “kill.” As noted by James A. Bowen in his 1900 book, “The digraph ln, n silent, occurs in kiln. A fall down the kiln can kill you.” However, today, most American English speakers pronounce the “n.” This change highlights how language, much like kiln technology, adapts with use and context. The word has carried its essential meaning through time, always tied to the process of burning or firing.

The Origins of Pottery Kilns in Ancient Societies

The first pottery kilns emerged alongside the rise of settled communities. Archaeologists have traced their earliest forms to sites like Yarim Tepe, dating back to around 6000 BCE. Early kilns marked a major advancement from simple open fire pits, as they allowed for higher, more consistent firing temperatures. These ancient kilns revealed new possibilities for pottery production and durability, setting the stage for future technological progress.

Let’s explore the archaeological discoveries that provide a window into these early inventions.

Early Evidence and Archaeological Discoveries

Discoveries at the Yarim Tepe site in modern Iraq show some of the earliest surviving pottery kilns, dating to around 6000 BCE. These kilns featured a double-chambered design, with a clay grate above the firing chamber, suggesting an understanding of how to separate fuel from wares and manage heat. The dome-shaped, updraft structure minimized heat loss and improved control over firing temperatures.

Such finds reveal a major leap from pit firing. Archaeologists have also uncovered remnants of early Egyptian vented kilns and Greek beehive kilns, each displaying unique adaptations. The progression of kiln technology—from open fires to chambered updraft designs—not only improved ceramic durability but also enabled larger-scale production.

These archaeological discoveries have taught us how ancient builders balanced resource constraints and technical challenges to create reliable pottery kilns, reflecting the ingenuity of early communities.

The Role of Pottery in Daily Life and Rituals

Pottery was woven into every aspect of ancient life, serving as containers for water, food storage, cooking, and trade. The quality and type of ware produced depended closely on the firing process handled within these early kilns. In daily routines, sturdy, well-fired pottery meant safer storage and easier meal preparation, improving the quality of life.

Beyond function, pottery also played a role in rituals and ceremonies. Special vessels were crafted for religious offerings or burial goods. The firing process, particularly the temperature and atmosphere in the pottery kiln, shaped the finish and durability of these ritual items.

Advancements in firing techniques allowed artisans to experiment with glazes and colors, resulting in ceramics that were both functional and meaningful. As the quality of ceramics improved, so did their value in both daily use and spiritual contexts.

Constructing Ancient Pottery Kilns: Materials and Methods

Building a pottery kiln in ancient times required practical design and available materials. Early builders often chose locations close to natural resources, such as clay and limestone, and used simple mortars to hold structures together. Construction methods varied, but most involved shaping a firing chamber, sometimes dome-shaped, to trap heat and redirect airflow. Each component—from the walls to the firebox—served a specific purpose in achieving the desired firing results.

Let’s look closer at the materials and step-by-step construction techniques used.

Common Building Materials for Early Kilns

Ancient pottery kiln builders relied on materials found in their local environment. Their choices influenced the durability and efficiency of the final structure:

- Limestone: Provided a sturdy foundation and could withstand repeated heating cycles.

- Clay: Used to mold the kiln’s dome and walls, acting as both insulation and a barrier to retain heat.

- Mortar: Typically made from mud or a mix of clay and ash, this held stones or bricks together.

- Firewood: Essential as fuel, affecting both the firing temperature and the final outcome of the pottery.

Archaeologists have found that some early kilns incorporated bricks or stacked stone, while others—such as Greek or Japanese designs—used combinations of clay, stone, and mortar to fit regional needs. The careful selection of materials was critical for reaching and maintaining high temperatures necessary for firing ceramics.

Step-by-Step Construction Techniques

Building an ancient pottery kiln followed a series of methodical steps, each designed to optimize firing conditions. Here’s how early potters typically approached the process:

- Site Selection: Builders chose locations close to water, clay, and fuel sources.

- Foundation: A base of limestone or stone was laid to support the kiln’s weight and protect it from ground moisture.

- Firing Chamber Construction: Layers of clay and stone were shaped into a dome or cylindrical form, with an opening for loading wares and managing air flow.

- Grate or Platform: Clay grates or shelves separated the pottery from direct flames, improving heat circulation.

- Chimney and Vents: Openings or chimneys were integrated to enhance air flow and control the firing atmosphere.

These construction steps ensured that the kiln could reach and sustain the temperatures necessary for successful pottery firing, while minimizing heat loss and structural damage.

Comparing Kiln Types Across Ancient Civilizations

Ancient civilizations around the world developed distinct types of kilns, each reflecting local materials, climate, and potters’ preferences. From the updraft beehive kilns of Greece to the long dragon kilns in China and the innovative climbing kilns in Japan, design differences shaped the firing process and final ceramic quality. Understanding these variations helps us appreciate how each civilization addressed the technical challenges of firing pottery.

We’ll now explore two broad categories: pit kilns and surface firing, followed by updraft and downdraft kilns.

Pit Kilns and Surface Firing

Pit kilns mark the earliest stage in pottery firing technology. These simple structures involved digging a hole or trench in the ground, placing pottery inside, and covering it with firewood, dung, or other combustibles. The earth’s insulation allowed the fire to reach higher temperatures than open-air firings, yet results were often inconsistent.

Surface firing, similar in practice, involved stacking pottery above ground, then piling fuel around and over it. Both methods lacked direct temperature control or air flow management, making outcomes unpredictable. Ceramics fired in pit or surface kilns were sometimes brittle or underfired but could be produced with minimal construction.

While pit kilns remained common for centuries, advances in kiln design—like updraft and downdraft methods—eventually provided better heat retention, higher temperatures, and greater reliability. These improvements laid the groundwork for more sophisticated ceramic production.

What are Updraft and Downdraft Kilns?

Updraft and downdraft kilns marked a leap in kiln design, enabling greater control over air flow and firing temperatures. Updraft kilns directed hot gases upwards through the firing chamber, out an opening or chimney at the top, while downdraft kilns forced gases downwards before venting them.

Key differences can be summarized in the table below:

| Feature | Updraft Kiln | Downdraft Kiln |

| Air Flow Direction | Upwards through ware, exits at top | Downwards, exits through side chimney |

| Heat Distribution | Less even, hotter at top | More even throughout chamber |

| Firing Efficiency | Moderate | Higher, with improved temperature control |

| Construction | Generally simpler, often dome-shaped | Complex, with separate firebox and chamber |

| Typical Civilizations | Greece, Egypt, early Mesopotamia | Medieval/Renaissance Europe, China (later) |

Updraft kilns were easier to build and manage for small batches. Downdraft kilns, though more complex, allowed for larger-scale production and more uniform ceramic quality due to better temperature control.

Ancient Greek Pottery Kilns and Their Innovations

Greek kiln technology brought significant refinement to the art of pottery firing. Their beehive-shaped kilns, often partly buried in the ground, featured well-designed air flow and firebox systems to reach desired temperatures. Greek innovations allowed for large-scale production and experimentation with glazes and finishes, making their ceramics world-renowned.

Let’s take a closer look at the structure and processes that set Greek pottery kilns apart from others of the era.

Structure and Layout of Greek Kilns

Greek kilns were known for their beehive or dome-shaped construction, usually supported by a limestone or brick foundation. The main elements included a lower firebox, where fuel was burned, and an upper chamber where the pottery was stacked on grates or shelves. A central chimney or vent allowed hot gases to escape, while air inlets at the base helped control combustion.

This layout kept the ware separate from direct flames, reducing the risk of uneven firing or soot deposits. The dome shape promoted efficient circulation of hot air, ensuring more uniform temperature distribution. Archaeologists have uncovered Greek kiln sites with evidence of carefully engineered walls, grates, and chimneys—all working together to enhance firing reliability.

Such innovations made it possible for Greek potters to produce large volumes of pottery with consistent quality and complex surface decoration.

Distinctive Greek Firing Processes

The Greek firing process was highly controlled and involved multiple stages to achieve distinctive finishes. The first phase, oxidation, introduced ample air through vents, allowing the pottery to heat evenly. After reaching a critical temperature, potters reduced the air supply, creating a reduction atmosphere that altered the color and texture of both the clay and any applied glazes.

By tightly managing air flow using adjustable vents and chimneys, Greek potters could hit the desired temperature for each part of the process. The result was signature red-and-black pottery, created by switching between oxidizing and reducing atmospheres.

Glaze application and the precise manipulation of firing conditions set Greek ceramics apart. Their process demonstrated not just technical know-how but also creative mastery, influencing pottery traditions across the Mediterranean for centuries.

The Six Ancient Japanese Kilns: Features and Influence

Japan’s six ancient kilns played a foundational role in shaping its ceramic traditions. Each kiln, from the Anagama to the Sue, showcased distinct architectural and technological features. These Japanese kilns not only reflected regional resources and needs but also fostered innovations in porcelain and stoneware. Their influence extended beyond Japan, becoming a cornerstone of East Asian kiln technology and ceramic artistry.

Let’s examine the architectural uniqueness and cultural impact of these celebrated kilns.

Unique Architectural Elements of Each Kiln

Japan’s ancient kilns were defined by their unique architecture and adaptation to local landscapes. The six famous kilns included:

- Anagama: A single-chamber, tunnel-like kiln built into a hillside, using gravity to aid airflow.

- Noborigama: A multi-chamber climbing kiln, also set on slopes, allowing heat to rise through successive firing chambers for greater efficiency.

- Other Regional Kilns: Such as the Sue and Bizen kilns, each with features customized to local clay, firing needs, and available fuels.

Distinct features included long, sloping chambers, thick clay walls for heat retention, and multiple stoking holes for precise temperature management. These elements enabled Japanese potters to reach high temperatures needed for porcelain and create a range of ceramic styles, from rustic stoneware to highly refined wares.

Impact on Japanese Ceramic Traditions

These ancient kilns played a pivotal role in the development of Japanese ceramic traditions. Their advanced kiln design enabled potters to fire porcelain and stoneware at higher, more consistent temperatures, which was previously difficult. The resulting ceramics were not only durable but also visually striking, with natural variations in glaze and surface texture.

The lineage of Japanese kiln technology is still alive today. Techniques honed using kilns like the Anagama and Noborigama are taught to new generations of potters, influencing everything from functional ware to fine art ceramics. The spread of kiln innovations throughout Japan also led to distinct regional styles, each celebrated for its unique qualities.

Japanese kilns set a standard for efficiency and artistry, leaving a lasting mark on global ceramic culture.

Firing Techniques: How Ancient Kilns Achieved Desired Results

Firing techniques in ancient pottery kilns were crucial for achieving durable, aesthetically pleasing ceramics. Potters adjusted air flow, fuel type, and firing duration to reach the desired temperature and atmosphere within the kiln. These variables directly influenced the finish, color, and structural integrity of the ware. Understanding the steps and science behind these firing processes helps us appreciate both the artistry and technical skill required of ancient ceramicists.

Let’s review the primitive firing methods, temperature control, and their effects on final products.

Primitive Pre-Kiln Firing Techniques

Before kilns became common, potters relied on primitive surface firing techniques. They would arrange pottery in open piles or shallow pits, surround the ware with firewood or dung, and ignite the fuel. While this method could achieve moderate temperatures, it was difficult to control, often resulting in unevenly fired pottery.

Early surface firing produced ceramics that were sometimes brittle and less durable, but still useful for daily and ritual purposes. The unpredictability of the process meant that many pieces broke or underfired, but those that survived reveal the creativity and adaptability of ancient craftspeople.

Despite its limitations, primitive firing offered valuable insights into heat management and air flow. These lessons paved the way for more enclosed kiln structures, where potters could better harness high temperatures for improved ceramic results.

Temperature Control and Management

Controlling temperature was one of the biggest challenges for ancient potters. Kiln design played a key role—strategically placed air inlets, adjustable vents, and chimneys allowed for better management of heat and air flow. Burners or fireboxes at the base of the kiln provided the initial heat source, while the shape and materials of the kiln helped retain temperature.

Potters learned to monitor color changes in the ware and the kiln’s interior to estimate temperature, long before thermometers existed. By adjusting the amount of fuel and air, they could influence the speed and evenness of the firing cycle.

Effective temperature control not only prevented cracking but also enabled the use of glazes, resulting in stronger, more visually appealing ceramics. These advances separated basic utility ware from the fine, decorated pottery still admired today.

Effects of Firing on Ceramic Appearance and Quality

The firing process determined more than just the hardness of ceramics—it shaped their entire appearance and performance:

- Glaze and Color: Controlling the atmosphere (oxidizing or reducing) in the kiln changed how glazes and clay bodies responded, leading to a variety of surface effects.

- Texture and Strength: Proper firing at the desired temperature reduced the porosity of the ware, making it more robust and water-resistant.

- Surface Finish: Quick or uneven firings could lead to blisters, cracks, or rough spots, while a well-managed process resulted in smooth, glossy surfaces.

Firing decisions affected whether pottery remained functional or decorative, and whether it could stand the test of time. Mastery of firing techniques was the hallmark of a skilled ancient potter.

Fuel Sources Used in Ancient Kilns

Fuel choice was central to the development of kiln technology. Ancient potters used locally available resources—firewood, hardwood, animal dung, and sometimes even lime—to achieve the high temperatures needed for firing. The type of fuel influenced the temperature, firing time, and final appearance of ceramics. Different civilizations adapted their kiln designs to work efficiently with their preferred fuels, highlighting the connection between environment and technological development.

Let’s explore the range of fuels used and their impact on the firing process.

Types of Fuel Available to Different Cultures

Ancient cultures selected fuel based on availability and performance. The most common types included:

- Firewood: Readily available and easy to burn, used by nearly all pottery traditions.

- Hardwood: Valued for its ability to burn hotter and longer, essential for reaching higher firing temperatures in advanced kilns.

- Animal Dung: Used in regions where wood was scarce; although harder to ignite and maintain, dung provided a supplemental heat source.

Other materials like rice chaff or straw were sometimes added to enhance combustion. Each culture’s choice of fuel shaped the design and construction of their kilns. For example, Japanese Anagama kilns were optimized for long, slow wood firings, while Mediterranean potters prioritized fuel that could reach desired temperatures quickly.

The diversity in fuel use reflects the adaptability of ancient potters to their environments.

How Fuel Choices Shaped Firing Outcomes

The type and quality of fuel influenced every stage of the firing process. Hardwoods allowed for longer, hotter firings, producing denser, more vitrified ceramics. Softwoods or dung, by contrast, burned cooler and faster, sometimes resulting in more porous ware.

Kiln design was often adapted to maximize the efficiency of available fuels. For example, long dragon kilns in China and climbing kilns in Japan were built to sustain the high temperatures needed for porcelain by burning vast amounts of wood. In Greece, fuel-rich regions enabled frequent, high-temperature firings, while arid regions saw more reliance on dung or straw.

Ultimately, fuel choice determined not just the technical performance of a kiln, but also the color, finish, and durability of the ceramics produced.

Recreating and Experimenting with Historical Kiln Designs Today

Modern archaeologists and pottery enthusiasts use experimental archaeology to recreate ancient pottery kilns and replicate historical firing processes. These reconstructions help answer questions about the challenges faced by ancient potters, the efficiency of historical designs, and the quality of pottery produced. By building and firing kilns using period-appropriate materials and methods, researchers deepen our understanding of ancient technology and craftsmanship.

Let’s examine how these reconstructions and experiments are conducted today.

Archaeological Reconstructions and Experimental Archaeology

Reconstructing ancient kilns is a hands-on process that blends archaeological research with practical experimentation. Researchers study excavated kiln sites, historical records, and surviving pottery to guide their reconstructions. This often involves:

- Sourcing Authentic Materials: Builders seek out limestone, clay, and mortar similar to what ancient potters used, sometimes importing materials from distant locations to match historical accuracy.

- Following Ancient Methods: Construction is carried out manually, piece by piece, using traditional tools and techniques.

- Testing Firing Processes: Experiments with various fuels—hardwood, softwood, and dung—reveal how each affected kiln performance and pottery outcomes.

Such projects not only validate historical theories but also offer unexpected insights. As Anne Johnakin ’23, a researcher who built a Greek-style kiln, noted: “I feel like I have a better appreciation for how much work was involved in building and using these kilns.”

Modern Enthusiasts Building Ancient-Style Kilns

Today, pottery enthusiasts and hobbyists are building ancient-style kilns at home, driven by a passion for traditional techniques. Many draw inspiration from archaeological studies, while others join online communities or attend masterclasses to learn the craft. They experiment with local materials—often improvising when specific resources like fire clay or limestone are scarce.

Builders document their construction methods, firing results, and challenges faced, contributing valuable data to the wider community. These projects often involve trial and error, as modern builders adapt ancient principles to modern conditions and regulations.

Recreating historical kilns reconnects practitioners to the roots of pottery making. It also provides a platform for public education, helping others appreciate the engineering and artistry behind ancient ceramics.

Significant Archaeological Discoveries Related to Pottery Kilns

Major archaeological finds have transformed our understanding of pottery kiln development. Sites like Yarim Tepe and ancient kiln complexes in Greece, China, and Japan provide direct evidence of construction methods, firing techniques, and cultural practices from thousands of years ago. These discoveries not only give us a glimpse into the daily lives of ancient potters but also reveal the technological advances that fueled broader social and economic progress.

We’ll now highlight some important excavations and the insights gained from these kiln sites.

Notable Excavations and Their Impact

Archaeologists have made significant finds at sites such as Yarim Tepe in Iraq, dating to 6000 BCE, and kiln complexes in Egypt, Greece, and China. The discovery of double-chambered, dome-shaped kilns at Yarim Tepe demonstrated an early leap in kiln technology, moving beyond basic pit firing.

Excavations in ancient Greece have uncovered well-preserved beehive kilns, while the identification of dragon kilns in China and climbing kilns in Japan has revealed the scale and sophistication of East Asian ceramic production. Roman industrial kilns, capable of firing tens of thousands of vessels at once, highlight the evolution of large-scale manufacturing.

Each excavation deepens our understanding of how ancient societies organized labor, sourced materials, and managed complex firing processes. These discoveries shape our view of technological progress across civilizations.

Insights Gained from Ancient Kiln Sites

Every kiln site offers a snapshot of ancient technology and daily life. By analyzing kiln remains, archaeologists learn about construction techniques, firing temperatures, and the organization of pottery workshops. For example, the presence of air flow channels and separate firing chambers at Greek and Roman sites shows deliberate design for efficiency and quality.

Pottery fragments found near kilns reveal the types of ware produced and the firing outcomes achieved—sometimes even the atmosphere inside the kiln, based on glaze and clay coloration. Kiln furniture such as grates, shelves, and firebars provides clues about loading strategies and batch sizes.

Understanding kiln technology helps archaeologists interpret broader patterns in trade, culture, and innovation. As Professor Julie Hruby remarks, “Anne’s research will contribute to our understanding of ancient Greek ceramic-firing technologies,” showing how each discovery fuels new questions and ideas.

Evolution of Kiln Technology from Antiquity to Modern Era

Kiln technology has witnessed remarkable evolution from simple pits to advanced industrial kilns. The transition from wood and dung as primary fuels to coal, gas, and finally electricity reflects ongoing improvements in efficiency and temperature control. The advent of digital controllers and remote monitoring in modern kilns has revolutionized the firing process, allowing for precision that ancient potters could only have dreamed of.

Let’s look at the major milestones in kiln design over time.

Key Milestones in Kiln Design Over Time

Kiln design has advanced through a series of transformative innovations:

- Pit and Surface Kilns: The earliest form, used for thousands of years, reflected the most basic approach to firing pottery.

- Chambered, Updraft, and Downdraft Kilns: Developments in Greece, Egypt, and China brought greater heat control, efficiency, and uniformity.

- Climbing and Dragon Kilns: In China and Japan, these designs enabled mass production of porcelain and stoneware, reaching temperatures up to 1400°C.

- Roman Industrial Kilns: Leveraging brick and concrete, the Romans built large, efficient kilns for mass production.

- Medieval and Renaissance Muffle Kilns: Innovations in Europe allowed for more artistic finishes through reduction firing.

- Industrial Age and Modern Kilns: The switch to coal, then gas and electricity, along with automated digital controllers, brought unparalleled precision and scale to ceramic firing.

These milestones chart a timeline of continuous adaptation and creativity, shaping both the art and science of ceramics.

Lasting Legacy of Ancient Techniques

Techniques developed over millennia continue to shape pottery practices today. The yarim tepe site and other archaeological discoveries reveal that ancient potters utilized specific kiln designs that optimized air flow and firing temperatures, laying the groundwork for modern kilns. Elements such as beehive kilns and updraft designs inform contemporary approaches, incorporating advancements in kiln technology, including electric and gas kilns. The principles of achieving the desired temperature for the firing process remain unchanged, demonstrating how these early innovations in ceramics have forged an enduring legacy that inspires today’s artisans and hobbyists alike.

The Role and Impact of Automatic Kiln Controllers in Modern Kilns

Automatic kiln controllers have revolutionized the firing process in modern kilns, significantly enhancing efficiency and precision. By meticulously regulating airflow and temperature, these advanced systems ensure that the desired temperature is reached uniformly, resulting in consistent and high-quality ceramics. The integration of automatic controllers enables potters to focus on creative aspects while minimizing the risks associated with manual monitoring. This balance of technology and artistry not only streamlines production but also extends the capabilities of contemporary kilns, allowing for experimentation with various materials and techniques across different types of kilns.

How to Build a Simple Primitive Pottery Kiln at Home

Constructing a simple primitive pottery kiln at home can be a rewarding experience that connects you to ancient practices. Begin by choosing a site with proper air flow—ensuring good ventilation is key to achieving high temperatures during the firing process. Many enthusiasts opt for a beehive kiln design, which utilizes an updraft system to facilitate efficient heat distribution. Use materials such as firewood or hardwood in the firebox, and ensure your kiln’s firing chamber is well-constructed with limestone or mortar to withstand the intense conditions during firings.

Materials Needed for a Basic Kiln

Constructing a basic pottery kiln requires several essential materials, each contributing to the overall functionality and efficiency of the firing process. A sturdy frame can be made from fire-resistant bricks or cement blocks, ensuring durability at high temperatures. Mortar is crucial for sealing gaps and enhancing structural integrity. Additionally, a reliable chimney allows for proper air flow, promoting an even heat distribution throughout the firing chamber. Insulation materials, like ceramic fiber blankets, are necessary to retain heat and maintain the desired temperature. For fuel, hardwood or firewood can be utilized to create an effective firebox, while metal rods serve as supports for the pottery ware during firings. Selecting the right combination of materials will greatly influence the kiln’s performance and the quality of the finished ceramics.

Step-by-Step Guide to Construction and Firing

Begin by gathering necessary materials, including firewood, limestone, and sturdy bricks to construct the kiln structure. Create the firing chamber, ensuring optimal air flow by designing an effective chimney and firebox. As you build, pay attention to kiln technology; a beehive or updraft design can enhance efficiency. Once assembled, season the kiln by firing it with scrap wood to stabilize. Plan your firings carefully, raising to the desired temperature slowly. Monitor the process closely to achieve the perfect pottery glaze, allowing pieces to mature within this ancient tradition of craftsmanship.

Can Ancient Pottery Kilns Still be Used Today by Hobbyists?

Yes, ancient pottery kilns can still be utilized by hobbyists today. Many enthusiasts appreciate the traditional methods and unique results they offer. While modern technology has its advantages, replicating these ancient techniques connects artists to history and enhances their craft experience.

Non-Ceramic Uses of Kilns

Kilns extend their utility far beyond ceramics, finding applications in various industrial sectors. One notable use is in wood-drying processes, where precise control of air flow and temperatures ensures optimal moisture removal, enhancing the wood’s durability. Furthermore, in the industrial age, kilns have evolved to accommodate diverse materials, such as limestone for lime production, and serve as essential components in manufacturing systems. Industries utilize advanced kiln designs, including beehive kilns and electric kilns, to achieve high temperatures necessary for firing processes in various material treatments.

The exploration of ancient pottery kilns reveals a rich tapestry of historical techniques and innovations that have shaped artistry across civilizations. From the construction methods observed at sites like Yarim Tepe to the advancement of kiln technology, the journey from simplistic designs to modern solutions illustrates humanity’s quest for perfection in ceramics. As potters today engage with the age-old practices of firing ware, they keep the legacy alive, honoring the craftsmanship that has endured through millennia. This connection bridges the past with contemporary creations, highlighting the timeless nature of art and its evolution.